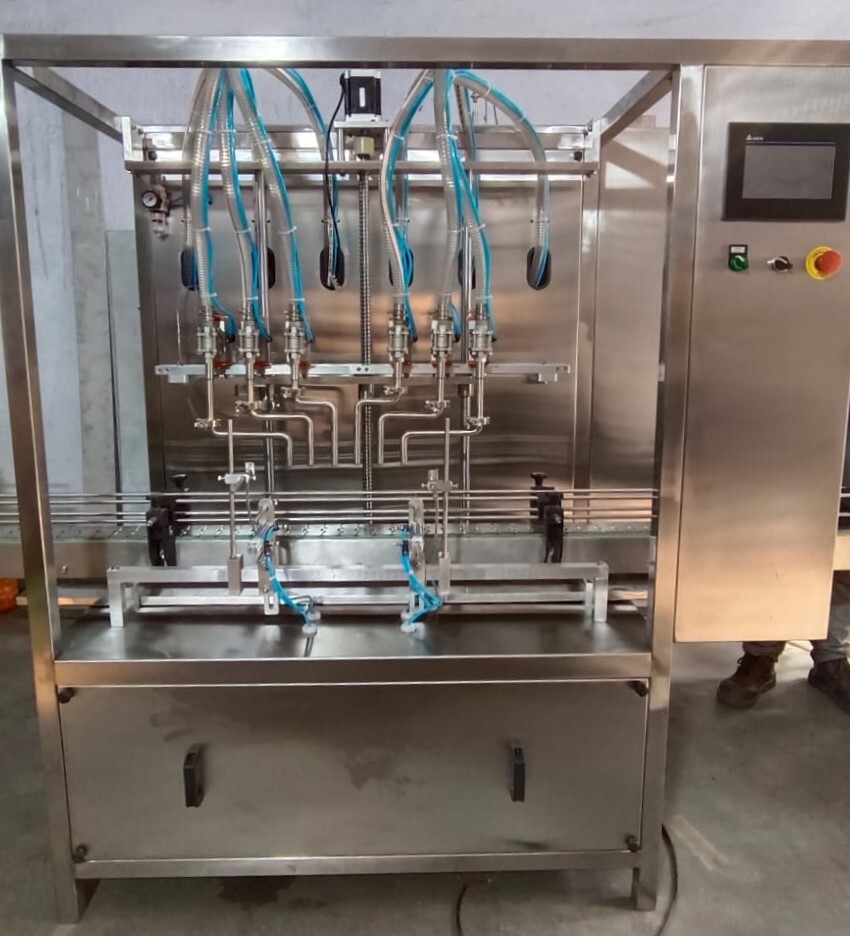

Automatic Mustard Oil Filling Machine

Automatic Mustard Oil Filling Machine Specification

- Product Type

- Ghee Filling Machine

- Material

- Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Weight (kg)

- 600 Kilograms (kg)

- Dimension (L*W*H)

- 1500 x1300 x 1200 mm Millimeter (mm)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency, Simple Control

- Color

- Silver

- Warranty

- 1 Year

Automatic Mustard Oil Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmadabad

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 1 Months

- Main Export Market(s)

- Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

About Automatic Mustard Oil Filling Machine

An Automatic Ghee Filling Machine is designed to fill containers with ghee (clarified butter) with precision and efficiency. These machines are widely used in dairy product manufacturing units to ensure consistent and hygienic filling processes. Heres a detailed description and specification of such a machine:

Description

The Automatic Ghee Filling Machine is engineered to automate the filling process of ghee into various types of containers such as jars, bottles, or pouches. The machine ensures a high level of accuracy and efficiency, maintaining the quality and hygiene standards required in the food industry. It typically operates using a combination of mechanical, electrical, and pneumatic systems to achieve the desired filling volume and speed.

Key Features

1. Precision Filling Equipped with advanced volumetric or gravimetric filling systems to ensure accurate fill volumes.

2. Hygienic Design Made with food-grade materials (like stainless steel) to ensure sanitary conditions.

3. Automation Programmable logic controllers (PLCs) and touch-screen interfaces for easy operation and customization.

4. Speed and Efficiency Capable of filling multiple containers simultaneously, with adjustable speed settings.

5. Versatility Can handle various container sizes and types with minimal adjustments.

6. Easy Cleaning and Maintenance Designed for easy disassembly and cleaning to comply with food safety standards.

7. Safety Features Equipped with safety guards and emergency stop functions to protect operators.

Specifications

The specifications can vary based on the model and manufacturer, but a typical specification sheet might look like this:

- Filling Capacity 100 ml to 5000 ml (customizable based on requirements)

- Filling Speed 20 to 100 containers per minute (depends on container size and product viscosity)

- Accuracy 1% of fill volume

- Power Supply 220V/380V, 50Hz/60Hz

- Air Pressure 0.6 to 0.8 MPa (for pneumatic components)

- Material Food-grade stainless steel (SS304 or SS316)

- Control System PLC with HMI (Human-Machine Interface) touch screen

- Dimensions Approximately 2000 mm (L) x 1200 mm (W) x 1800 mm (H)

- Weight 500 to 1000 kg (varies by model)

- Container Types Jars, bottles, pouches (customizable)

- Nozzle Types Single or multiple nozzles for high-speed filling

- Additional Features

- Anti-drip mechanism

- Automatic container feeding and discharge

- Adjustable filling heads for different container sizes

Optional Add-ons

1. Capping and Sealing Integrated systems for automatic capping and sealing of containers.

2. Labeling Automated labeling machines for applying labels to filled containers.

3. Conveyors For seamless movement of containers through different stages of filling, capping, and labeling.

4. Heating System To maintain the ghee at the desired temperature for filling.

Applications

- Dairy product manufacturing plants

- Food processing units

- Small and medium-scale ghee production businesses

An Automatic Ghee Filling Machine not only enhances productivity but also ensures that the product is filled under sanitary conditions, maintaining its quality and extending shelf life..

FAQs of Automatic Mustard Oil Filling Machine:

Q: What is the voltage requirement for the Automatic Mustard Oil Filling Machine?

A: The machine operates at a voltage of 220 Volt (v).Q: What type of control system is used in this filling machine?

A: The machine uses a PLC (Programmable Logic Controller) control system.Q: Is the Automatic Mustard Oil Filling Machine computerized?

A: Yes, the machine is fully computerized for efficient operation.Q: What are the dimensions of the machine?

A: The dimensions are either 1200 x 1000 x 1800 Millimeter (mm) or 1500 x 1300 x 1200 Millimeter (mm), depending on the model.Q: What are the key features of this machine?

A: The machine features high performance, eco-friendly operation, low noise, lower energy consumption, high efficiency, and simple control.Q: What is the warranty period for the Automatic Mustard Oil Filling Machine?

A: The machine comes with a 1-year warranty.Q: What material is used in the construction of this machine?

A: The machine is constructed using steel for durability and robustness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Filling Machine Category

Automatic Groundnut Oil Filling Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 years

Automatic Grade : Automatic

Weight (kg) : 500 Kilograms (kg)

Control System : PLC Control

Automatic Automotive Oil Filling Line

Price 60000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 years

Automatic Grade : Automatic

Weight (kg) : 500 Kilograms (kg)

Control System : PLC Control

Automatic Oil Tin Filling Machine

Price 60000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 years

Automatic Grade : Automatic

Weight (kg) : 400 Kilograms (kg)

Control System : PLC Control

Automatic Synthetic Oil Filling Machine

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 years

Automatic Grade : Automatic

Weight (kg) : 400 Kilograms (kg)

Control System : PLC Control

Send Inquiry

Send Inquiry