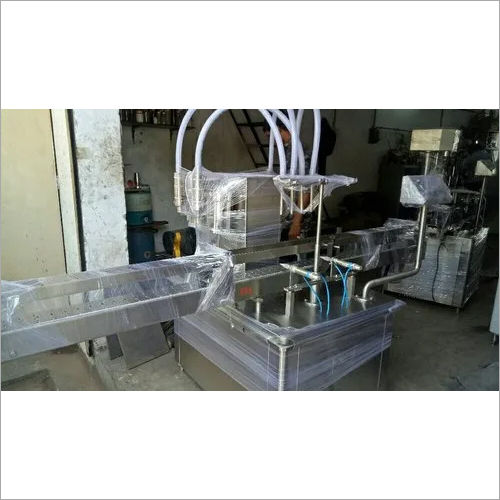

Automatic Four Head Liquid Filling Machine

Automatic Four Head Liquid Filling Machine Specification

- Product Type

- Filling Machine

- Material

- Steel

- Packaging Material

- Glass, Plastic

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Weight (kg)

- 400 Kilograms (kg)

- Dimension (L*W*H)

- 1200 x900x 1000 Millimeter (mm)

- Color

- Silver

- Warranty

- 1 Year

Automatic Four Head Liquid Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mundra

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 20 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Automatic Four Head Liquid Filling Machine

Description of Automatic Four Head Liquid Filling Machine

An Automatic Four Head Liquid Filling Machine is designed for efficient, precise, and rapid filling of liquid products into various types of containers, such as bottles, jars, and vials. These machines are extensively used in industries such as pharmaceuticals, cosmetics, food and beverage, and chemicals, where consistent and accurate filling is crucial. The machine is equipped with four filling heads, allowing it to fill multiple containers simultaneously, thereby increasing production efficiency.

Key Features

1. Multiple Filling Heads Four filling heads operate simultaneously, significantly boosting productivity.

2. High Precision Advanced volumetric or gravimetric filling systems ensure accurate filling volumes.

3. User-Friendly Interface Equipped with PLC and HMI (Human-Machine Interface) touch screens for easy operation and parameter settings.

4. Versatility Capable of handling a wide range of liquid viscosities and container sizes with minimal adjustments.

5. Hygienic Design Constructed with food-grade stainless steel to maintain sanitary conditions and ease of cleaning.

6. Adjustable Speed Variable speed control to match production requirements.

7. Anti-Drip System Nozzles are designed to prevent drips and spills, ensuring clean and efficient filling.

8. Automated Operation Automatic container feeding, positioning, and discharge for seamless operation.

9. Safety Features Safety guards and emergency stop buttons to protect operators.

Specifications

- Filling Capacity 50 ml to 5000 ml (customizable based on requirements)

- Filling Speed 30 to 120 containers per minute (depends on container size and liquid viscosity)

- Accuracy ï1% of fill volume

- Power Supply 220V/380V, 50Hz/60Hz

- Air Pressure 0.6 to 0.8 MPa (for pneumatic components)

- Material Food-grade stainless steel (SS304 or SS316)

- Control System PLC with HMI touch screen

- Dimensions Approximately 2200 mm (L) x 1300 mm (W) x 1900 mm (H)

- Weight 600 to 1200 kg (varies by model)

- Container Types Bottles, jars, vials (customizable)

- Nozzle Types Four filling nozzles for high-speed filling

- Additional Features

- Anti-drip mechanism

- Automatic container feeding and discharge

- Adjustable filling heads for different container sizes

Optional Add-ons

1. Capping and Sealing Integrated systems for automatic capping and sealing of containers.

2. Labeling Automated labeling machines for applying labels to filled containers.

3. Conveyors For seamless movement of containers through different stages of filling, capping, and labeling.

4. Heating System To maintain liquids at the desired temperature for filling, especially for viscous products.

5. Nitrogen Flushing For applications requiring inert gas to prevent oxidation of the product.

Applications

- Pharmaceutical Industry Filling medicines, syrups, and other liquid drugs.

- Cosmetics Industry Filling lotions, shampoos, conditioners, and other personal care products.

- Food and Beverage Industry Filling sauces, juices, oils, and other edible liquids.

- Chemical Industry Filling detergents, cleaning solutions, and other chemical liquids.

The Automatic Four Head Liquid Filling Machine is designed to enhance productivity, maintain product quality, and ensure consistent filling accuracy. Its robust construction, combined with advanced automation, makes it an ideal solution for medium to large-scale production facilities.

FAQs of Automatic Four Head Liquid Filling Machine:

Q: What are the dimensions of the Automatic Four Head Liquid Filling Machine?

A: The dimensions of the machine are 1600 x 800 x 1800 Millimeter (mm) and 1200 x 900 x 1000 Millimeter (mm).Q: What is the warranty period provided for this machine?

A: The Automatic Four Head Liquid Filling Machine comes with a 1-year warranty.Q: What is the weight range of this machine?

A: The machine weighs 350 Kilograms (kg) and 400 Kilograms (kg), depending on the configuration.Q: What type of drive system does this machine use?

A: The machine operates on an electric drive system.Q: What type of packaging materials are supported by this machine?

A: The machine supports packaging materials such as Glass and Plastic.Q: What is the control system used in this machine?

A: The machine is equipped with a Frequency Speed Control system.Q: What is the power and voltage requirement of the machine?

A: The machine requires 220 Volt (v) power to operate.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Ghee Bottle Filling Machine

Price 330000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Mustard Oil Filling Machine

Warranty : 1 Year

Automatic Grade : Automatic

Control System : Frequency Speed Control

Ghee Filling And Sealing Machine

Price 280000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Ghee Filling Machine

Warranty : 1 Year

Automatic Grade : SemiAutomatic

Control System : Human Machine Interface

Industrial Bottle Filling Machine

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Filling Machine

Warranty : 1 Year

Automatic Grade : Automatic

Control System : Human Machine Interface

Stainless Steel Electric Bottle Filling Machine

Price 640000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Filling Machine

Warranty : 1 Year

Automatic Grade : Automatic

Control System : PLC Control

Send Inquiry

Send Inquiry