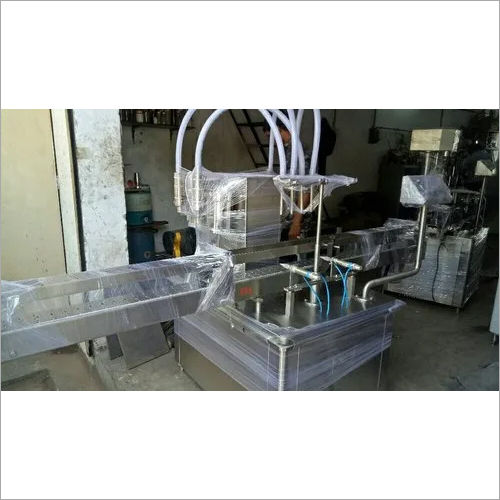

Ghee Bottle Filling Machine

Ghee Bottle Filling Machine Specification

- Product Type

- Mustard Oil Filling Machine

- Material

- Steel

- Packaging Material

- Paper, Plastic, Glass

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Weight (kg)

- 350 Kilograms (kg)

- Dimension (L*W*H)

- 1200 x900x 1000 Millimeter (mm)

- Feature

- Lower Energy Consumption, ECO Friendly, Low Noise, High Efficiency, Simple Control, High Performance, Stable Performance

- Color

- Silver

- Warranty

- 1 Year

Ghee Bottle Filling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mundra

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 15 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Ghee Bottle Filling Machine

An Automatic Four Head Liquid Filling Machine is a sophisticated piece of equipment designed to fill liquids into containers with high precision and efficiency. This type of machine is commonly used in various industries including pharmaceuticals, cosmetics, food and beverage, and chemicals. The four head design allows for simultaneous filling of multiple containers, significantly increasing production throughput.

Description

The Automatic Four Head Liquid Filling Machine automates the process of filling liquids into containers, ensuring accurate volume control and high-speed operation. It is designed to handle a wide range of liquid viscosities, from water-thin liquids to thicker, more viscous substances. The machine typically features a robust stainless steel construction for durability and hygiene, making it suitable for industries where cleanliness and precision are paramount.

Key Features

- Multi-Head Design: Four filling heads operate simultaneously to increase efficiency and throughput.

- High Precision: Advanced volumetric or gravimetric filling systems ensure accurate and consistent fill volumes.

- User-Friendly Interface: Equipped with a PLC and a touch-screen HMI (Human-Machine Interface) for easy operation and customization of settings.

- Versatility: Adjustable settings to accommodate different container sizes and shapes.

- Hygienic Construction: Made from food-grade stainless steel to meet stringent hygiene standards.

- Automatic Operation: Automated container feeding, filling, and discharge processes.

- Easy Maintenance: Designed for quick disassembly and cleaning to comply with sanitary regulations.

- Safety Features: Includes emergency stop functions and safety guards to protect operators.

Specifications

The specifications for an Automatic Four Head Liquid Filling Machine can vary, but a typical specification sheet might include:

- Filling Range: 10 ml to 5000 ml (adjustable based on requirements)

- Filling Speed: 40 to 80 containers per minute (depends on liquid viscosity and container size)

- Accuracy: ï1% of fill volume

- Power Supply: 220V/380V, 50Hz/60Hz

- Air Pressure: 0.6 to 0.8 MPa (for pneumatic components)

- Material: Food-grade stainless steel (SS304 or SS316)

- Control System: PLC with HMI touch screen

- Dimensions: Approximately 2000 mm (L) x 1200 mm (W) x 1800 mm (H)

- Weight: 600 to 1200 kg (varies by model)

- Container Types: Bottles, jars, and other containers (customizable)

- Nozzle Types: Four filling nozzles for simultaneous multi-container filling

FAQs of Ghee Bottle Filling Machine:

Q: What is the drive type of the Ghee Bottle Filling Machine?

A: The drive type of the Ghee Bottle Filling Machine is Electric.Q: What are the features of the Ghee Bottle Filling Machine?

A: The machine features lower energy consumption, eco-friendly operation, low noise, high efficiency, simple control, high performance, stable performance, heavy-duty design, durability, rust-proof material, and less power consumption.Q: What is the weight and dimension of the Ghee Bottle Filling Machine?

A: The machine weighs 550 kilograms and 350 kilograms with dimensions of 1200 x 1000 x 1800 millimeters and 1200 x 900 x 1000 millimeters.Q: What types of packaging materials are compatible with the Ghee Bottle Filling Machine?

A: The machine is compatible with paper, plastic, and glass packaging materials.Q: What is the warranty period of the Ghee Bottle Filling Machine?

A: The machine comes with a warranty period of 1 year.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Automatic Four Head Liquid Filling Machine

Price 380000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 350 Kilograms (kg)

Drive Type : Electric

Automatic Grade : Automatic

Voltage : 220 Volt (v)

Stainless Steel Electric Bottle Filling Machine

Price 640000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 350 Kilograms (kg)

Drive Type : Electric

Automatic Grade : Automatic

Voltage : 1 500 Volt (v)

Ghee Filling And Sealing Machine

Price 280000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 100 Kilograms (kg)

Drive Type : Electric

Automatic Grade : SemiAutomatic

Voltage : 1 500 Volt (v)

Industrial Bottle Filling Machine

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1 100 Kilograms (kg)

Drive Type : Electric

Automatic Grade : Automatic

Voltage : 1 500 Volt (v)

Send Inquiry

Send Inquiry